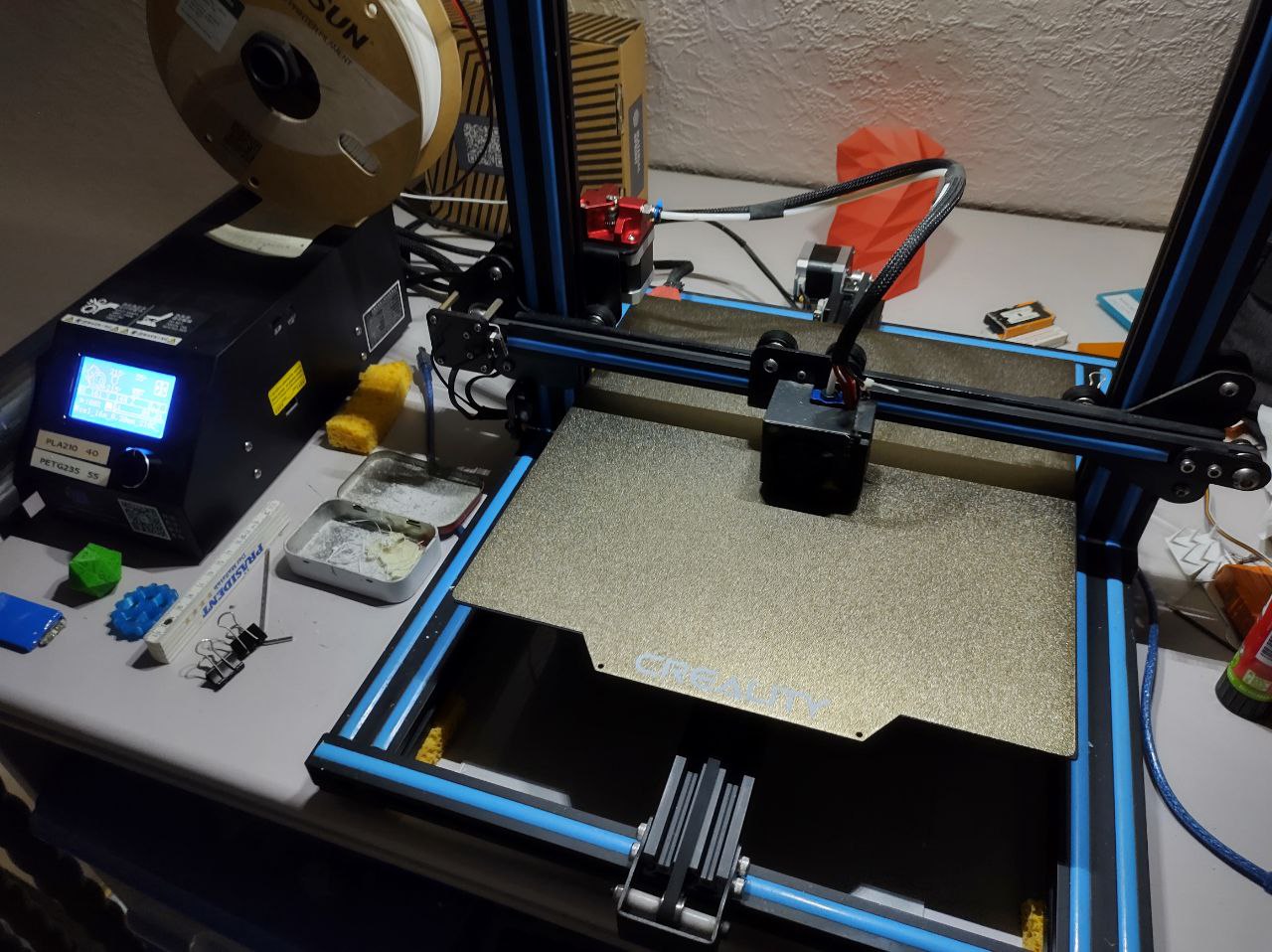

My Extruder is a little f***ed up. Let’s fix it.

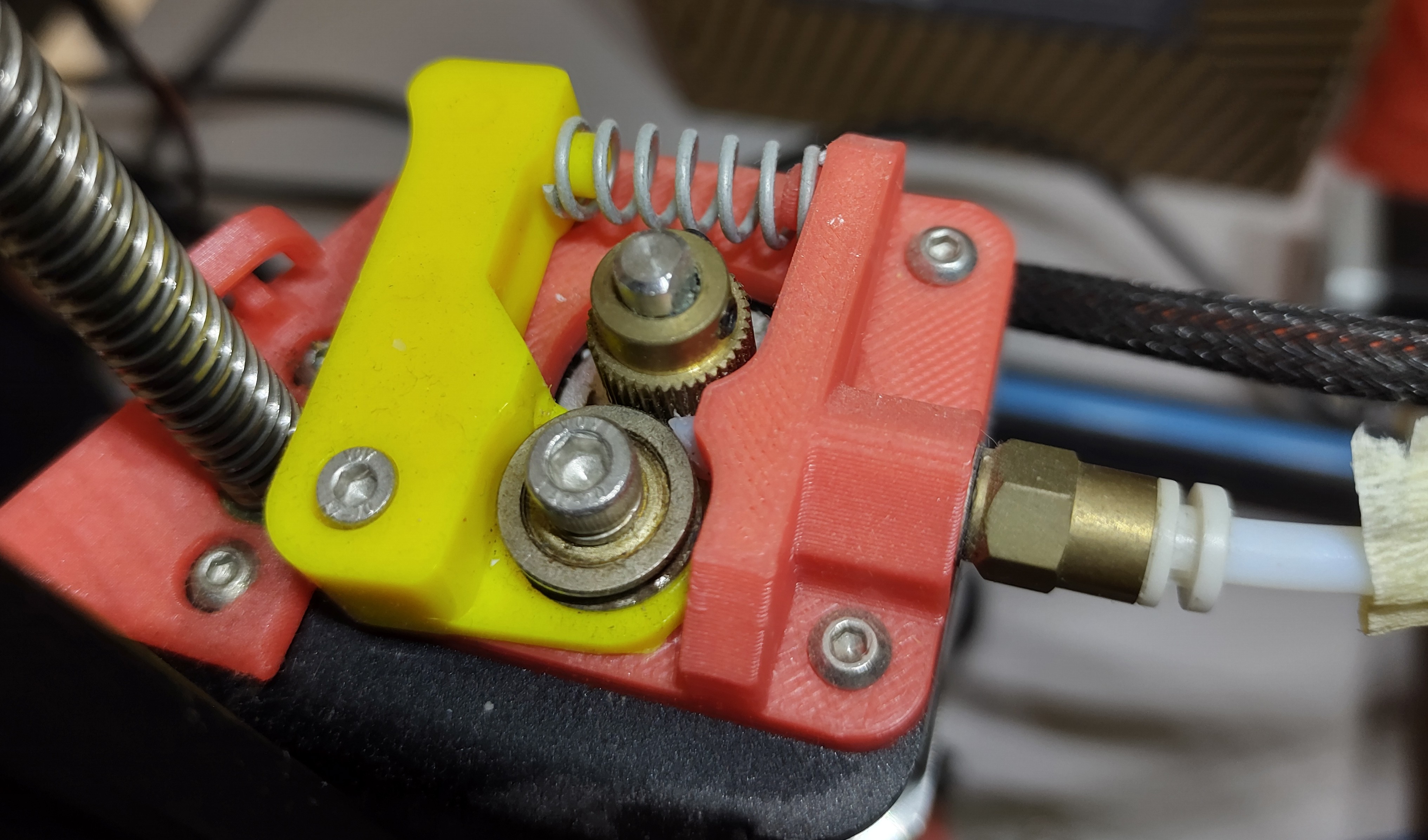

I actually don’t know if my Printer ever came with a clip for that Bowden tube fitting. I doubt it.

Issues

Whenever my printer wants to Retract after extrusion, and vice versa, it won’t for a short time, as there is slack in the Bowden tube. Changing from Extruding to Retracting has Lag. It also retracts less total length.

I could just replace the broken fitting, but there’s already a full metal extruder here, waiting to be installed.

The red part is 3D printed, and you can see the part flex where the spring presses against it.

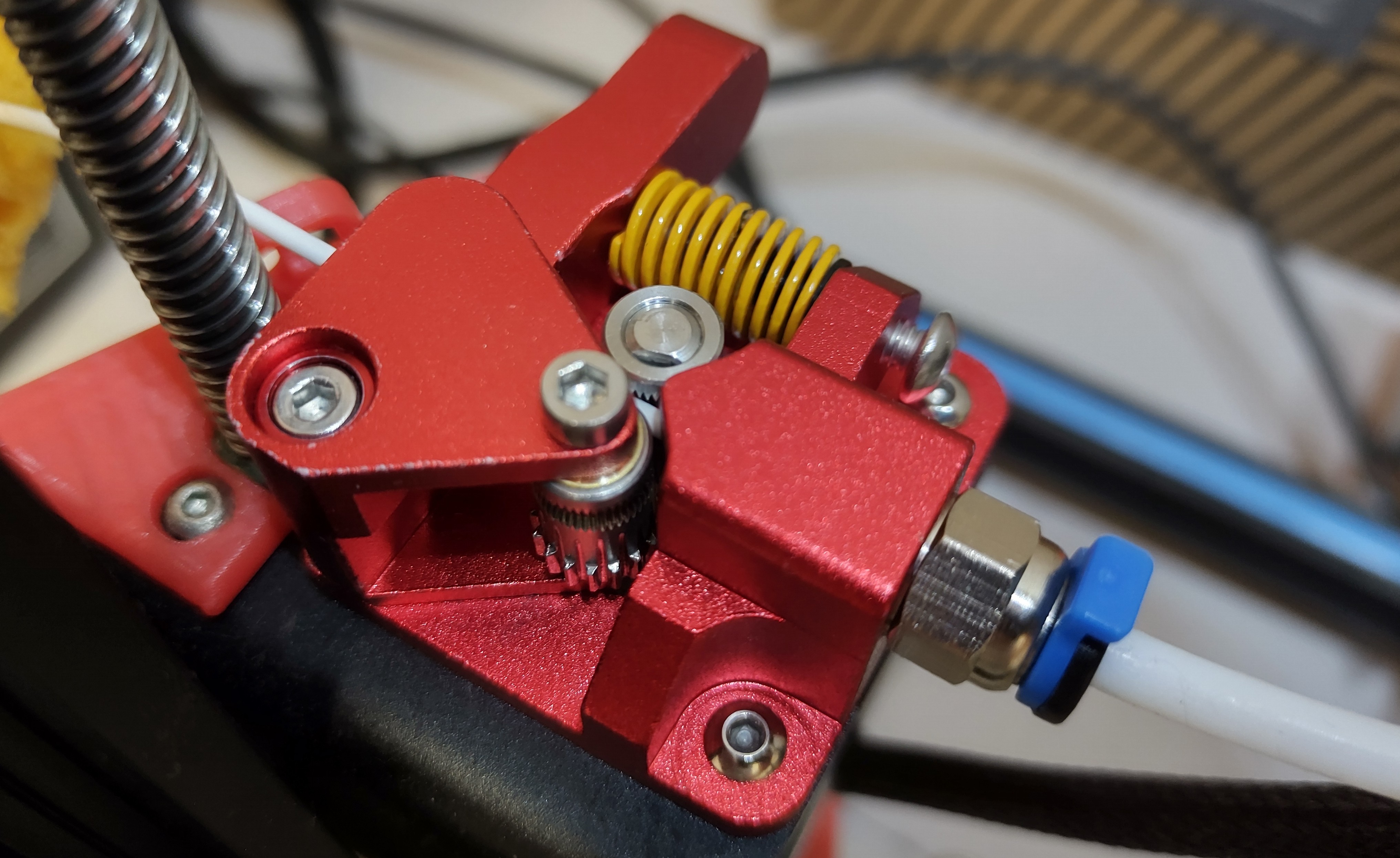

Extrude This!

It’s the AliExpress special: Cheap, took forever to get here, awful packaging, and it was cheap!

Installation was straightforward. Only critical parts of the Installation were proper Alignment of the teeth on the dual Drive Gears. And tightening the set screw on the stepper gear was tough.

E-Steps

Since the new extruder gears have a different diameter, we need to re-calibrate the E-Steps yet again. See my Previous post for more details, but here’s the TLDR:

- Mark your Filament, and note the length to your extruder for reference

- let the printer extrude 100 mm

- measure again, and note the difference (mine only extruded 77 mm)

- Repeat steps 2 & 3 a couple of times

- Calculate the Average

- Check your E-Steps value

- Calculate the new E-Steps and Store them in your printer

- Do a test extrusion of 100 mm

If you get 98 mm to 102 mm extruded, that will be totally fine. The last percent or two should be fine-tuned in your slicer anyway, per material. Different Materials get crushed differently by your extruder gears.

I calibrated mine just before the Extruder swap. The new extruder was only giving me 75 mm, when I was asking for 100 mm. I changed the E-Steps value in the custom firmware configuration (again) from 102.7 to 137.85.

Now its calibrated and ready to go.

Results

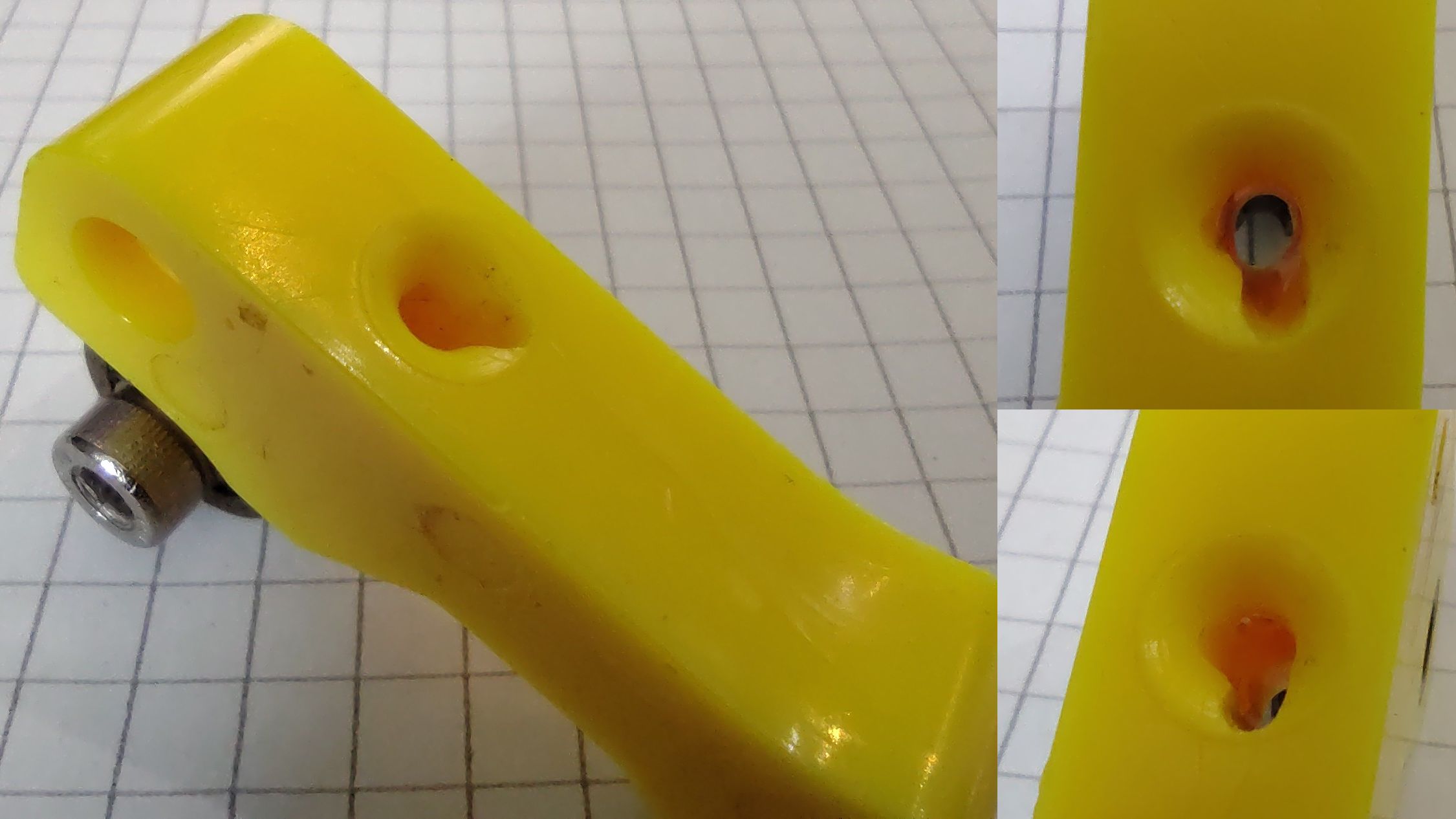

I’ve always had decent prints from my CR-10, but the new extruder and bed blow everything out of the water. Taking a closer look at my old extruder hardware, I noticed the Injection Molded Lever was quite worn out:

With every retraction, the filament would (After having received a set of teeth from the old extruder gear) grind away the lever. The Filament was probably on tension from the red filament guide I installed, to keep it away from the greasy Z Lead Screw! Insanity!

While we are here…

I also quickly changed the Glass bed out for the magnetic spring steel bed with PEI coating. It took a couple prints for me to realize I’ll never ever need glue stick again.